Vacuum Gauge & Vacuum Group unit

FT_ADCSI

The vacuum gauge system is used to monitor the vacuum value read by the sensor, which is connected to the vacuum pump under consideration.

A vacuum threshold can be assigned to the control unit to be considered as a target value to be reached during the vacuum process.

when the vacuum value read by the sensor is higher than the settled vacuum threshold FT_ADCSI gives out a red light signal.

when vacuum value read by sensor is lower than settled vacuum threshold ADCSI gives out a green light signal.

The vacuum gauge consists of:

- Edwards vacuum sensor model APG200 with Pirani technology.

- Wifi adapter, only for models that provide connection via wifi.

- Eaton Plc that allows to check the control unit display and access to all relevant functions.

- The enclosure is also equipped with two indicator lights:

- Green to indicate that the vacuum value is below the LOW threshold (VACUUM OK),

- Red to indicate that the vacuum value is over the HIGH threshold (VACUUM NOT OK)

- Power supply input – 230Vac 50/60 Hz

- LAN cable for vacuum signal input

FT Vacuum State Indicator

- Green (vacuum threshold reached)

- Red (vacuum threshold not reached)

The screen shows the following data:

- date and time of vacuum phase start.

- The vacuum level is indicated graphically by a progress bar on a logarithmic scale , of which the full scale corresponds to atmospheric pressure.

- Vacuum level expressed in Pascal

- Vacuum Threshold.

- Vacuum time.

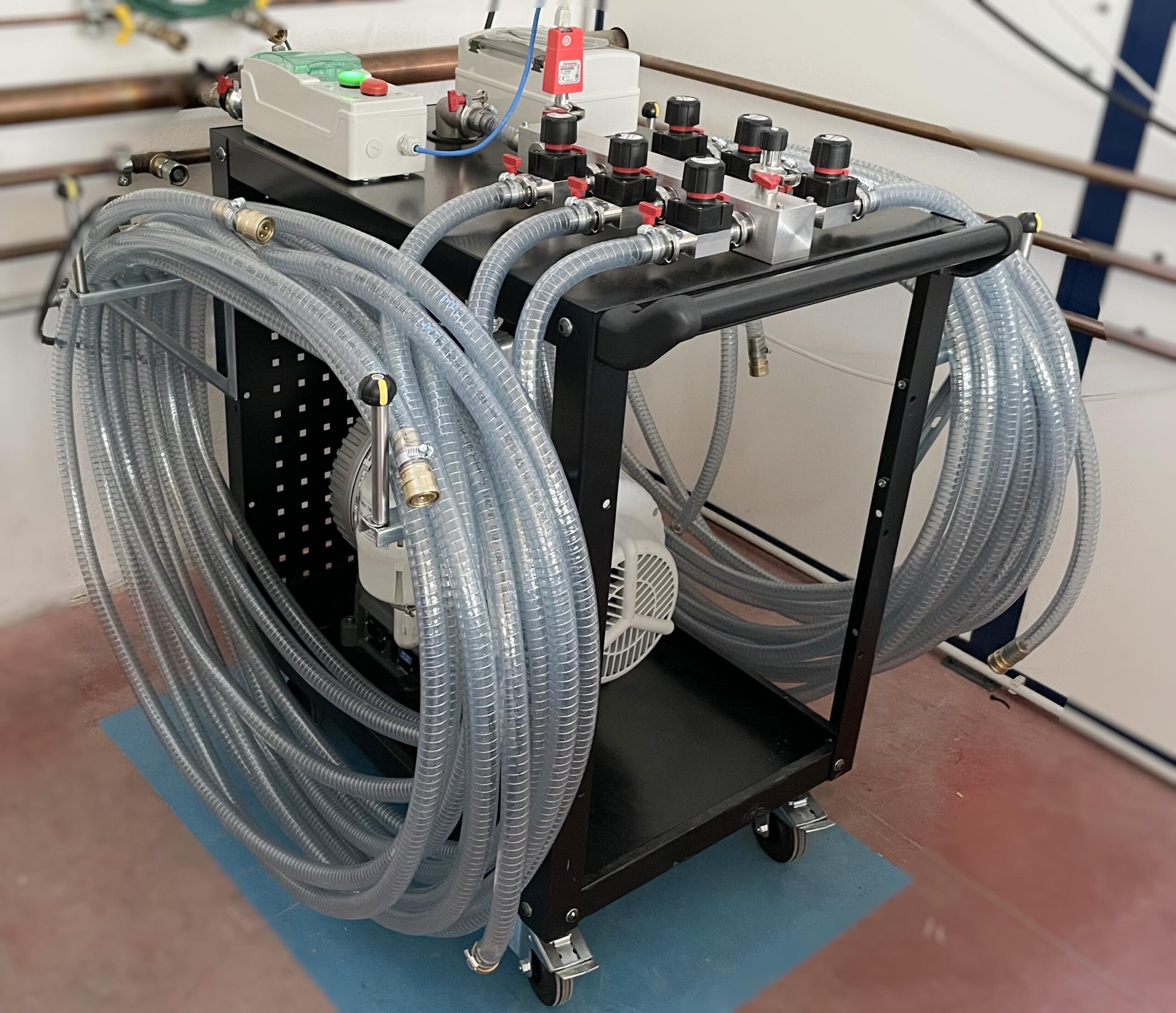

GV-XXX

GV-XXX is suitable for evacuation of refrigeration units in both to production and repair phases in industrial processes. Dry pumps represent an industry standard, used over many years proving to be a strong, and reliable vacuum execution solution in a wide range of applications.

The unit has an electrical control panel to enable operation of the vacuum pump and vacuum monitoring. They can be configured with relevant vacuum pipes according to customer requirements.

The exhaust line of the pump can be equipped with high efficiency filter that allows the recovery of the retained oil in order to reduce the consumption of oil by the vacuum pump.

Main features and accessories:

- Filter to protect the vacuum pump from liquids, such as compressor oil or moisture.

- Digital Pirani vacuum gauge with adjustable set point. Alternatively Vacuum State Indicator, with light indicators to show the vacuum status:

¨ Green to indicate that the vacuum value is below the LOW threshold (VACUUM OK),

¨ Red to indicate that the vacuum value is over the HIGH threshold (VACUUM NOT OK)

- Two lines of high conductance vacuum with quick Hansen F to connect the units to be evacuated

| Optional features and devices |

| Available pumps flow rates: 40, 80, 90 m3 / h |

| Up to eight lines of high conductance vacuum with quick Hansen Female |

Example of a multiple vacuum group for large refrigeration units in both initial production and repair.

Multiple vacuum group is consist of:

- Electrical panel Pump ignition and vacuum gauge

- Vacuum meter

- Vacuum Sensor

- Vacuum interceptor block for each pipeline

Tel. +39 0564 957385

VAT: IT 00871960522 • REA GR 85796

Privacy-Policy

FT S.r.l. "Future Technologies"

Via delle Sorgenti, 5

58033 Castel del Piano GR ITALY